[broadstreet zone=”80100″]

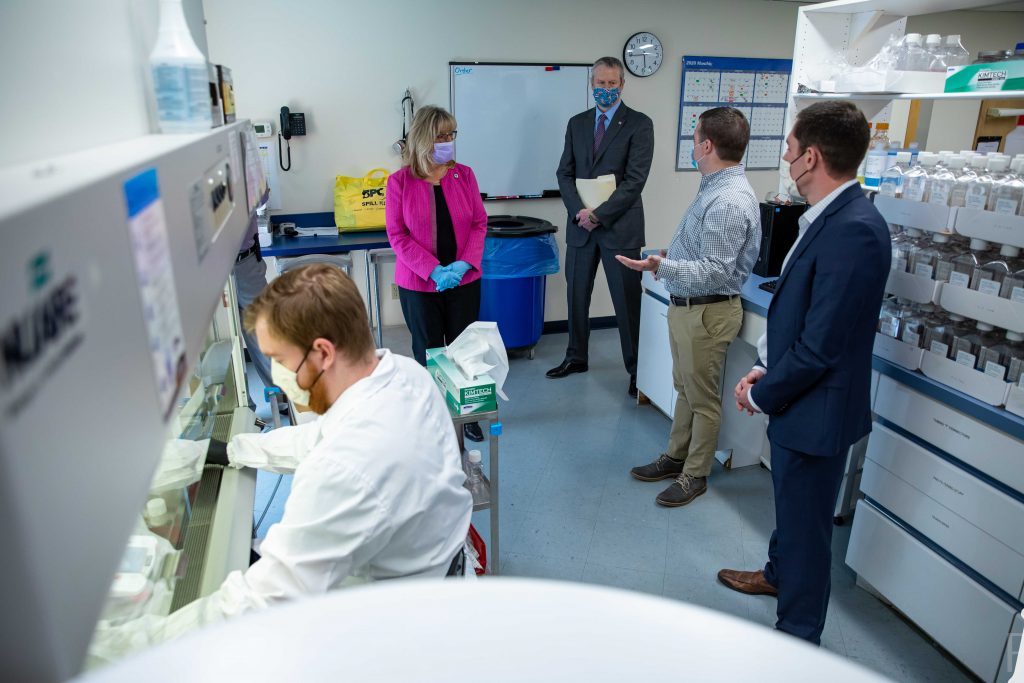

ASHLAND – Massachusetts Governor Charlie Baker today, May 12, toured Ashland-based MatTek Life Sciences, a company participating in the Baker-Polito Administration’s Manufacturing Emergency Response Team (M-ERT).

This initiative assists local manufacturers in transitioning operations to produce personal protective equipment (PPE) and other critical items needed to support the Commonwealth’s ongoing response to the COVID-19 public health emergency.

[broadstreet zone=”59982″]

Boasting a highly trained scientific staff, expertise in cell culture and building human tissues, and existing relationships with government agencies and the FDA, MatTek was uniquely positioned to shift their operations to support the Commonwealth’s response to COVID-19.

The transition from the manufacture of cell culture media to the production of viral transport media was streamlined with support from the M-ERT’s experts, particularly MIT’s System Design and Management program. The Ashland company received $40,000 from the program.

In MatTek’s normal operations, many of its 3D tissue types have been used in COVID-19 antiviral research – EpiAirway, EpiOral and EpiIntestinal – with the EpiAirway tissue being particularly relevant for this research, providing a human-based platform for scientists to get more relevant results much faster than if they used animals.

[broadstreet zone=”59984″]

In addition to providing essential products for COVID-19 research, six weeks ago MatTek also pivoted labs and staff into producing hand sanitizer, and has donated hundreds of liters to local first responders and medical facilities, and shipped thousands of liters across the country.

Senate President Karen Spilka, who lives in Ashland, joined Governor Baker on the tour.

MatTek CEO Alex Armento said his company has been involved in the fight against the coronavirus since day one.

Armento said his company sent over one of its lung tissue models to infectious disease experts at the National Institute of Allergy and Infectious Disease, to better study the COVID-19.

[broadstreet zone=”70107″]

The CEO said it was weird to see Route 135, outside the company’s facility, empty the day of the Marathon. MatTek is near Mile Marker 4 on the historic marathon route.

“Patriots Day is typically a day where more than 30,000 athletes come together and run by this building. With the streets quiet and bare, it really hit home that this COVID-19 challenge is a marathon, not a sprint,” said Armento.

MatTek is “dedicated to run this marathon,” said Armento.

“Ashland businesses have a history of retooling themselves to provide assistance to the state and nation in turning back threats both domestically and internationally,” said Ashland Town Manager Michael Herbert.

[broadstreet zone=”59983″]

MatTek has received grant support through the M-ERT’s funding program launched last month to substantially increase their output of viral transport media.

Armento said the company hopes to produce 10,000 units per week, of its new viral transport needed for the coronavirus testing.

When up to scale, the Ashland company hopes to produce 20,000 to 30,000 per week, he said.

“We appreciate Governor Baker’s interest in touring one of several businesses in Ashland, MatTek, to see how they are participating in the fight against COVID-19. Cooperation between the government, private, and nonprofit sectors will be the only way we can succeed against coronavirus,” said Herbert.

The Massachusetts Life Sciences Center is among the M-ERT partners that have made capital funding available to pivoting manufacturers.

The M-ERT is a coordinated response by the Baker-Polito Administration and leading academic and industry stakeholders to support the Commonwealth’s manufacturers in their efforts to produce much-needed supplies for front-line workers and the health care system. The M-ERT is led by the Massachusetts Technology Collaborative (MassTech) and members include representatives from: Massachusetts Life Sciences Center, Advanced Functional Fabrics of America (AFFOA), MIT, MIT Lincoln Labs, the University of Massachusetts Lowell, Worcester Polytechnic Institute (WPI), the Massachusetts Manufacturing Extension Partnership (MassMEP), Associated Industries of Massachusetts (AIM), and other industry partners.

[broadstreet zone=”58610″]

The M-ERT also launched $10.6 million in new funding to help manufacturers scale their operations to produce PPE and other critical items. Companies can apply for grants through an online form for equipment, materials, supplies, workforce training and other needs. A Review Committee will process applications based on criteria including production timeline and recommend grant awards.

The M-ERT has graduated 27 companies that have produced almost 3 million PPE items to date. As of Thursday, 704 companies in total have reached out to participate in the M-ERT initiative, including 434 from Massachusetts.

[broadstreet zone=”70106″]

***

Photos by the Governor’s office

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

[Joshua Qualls/Governor’s Press Office]

Photos courtesy of Ashland resident Jon Fetherston