By Luke Canavan

***

FRAMINGHAM – The Massachusetts Department of Environmental Protection (MassDEP) held a virtual meeting on Thursday, March 11 to discuss the cleanup of the former General Chemical site.

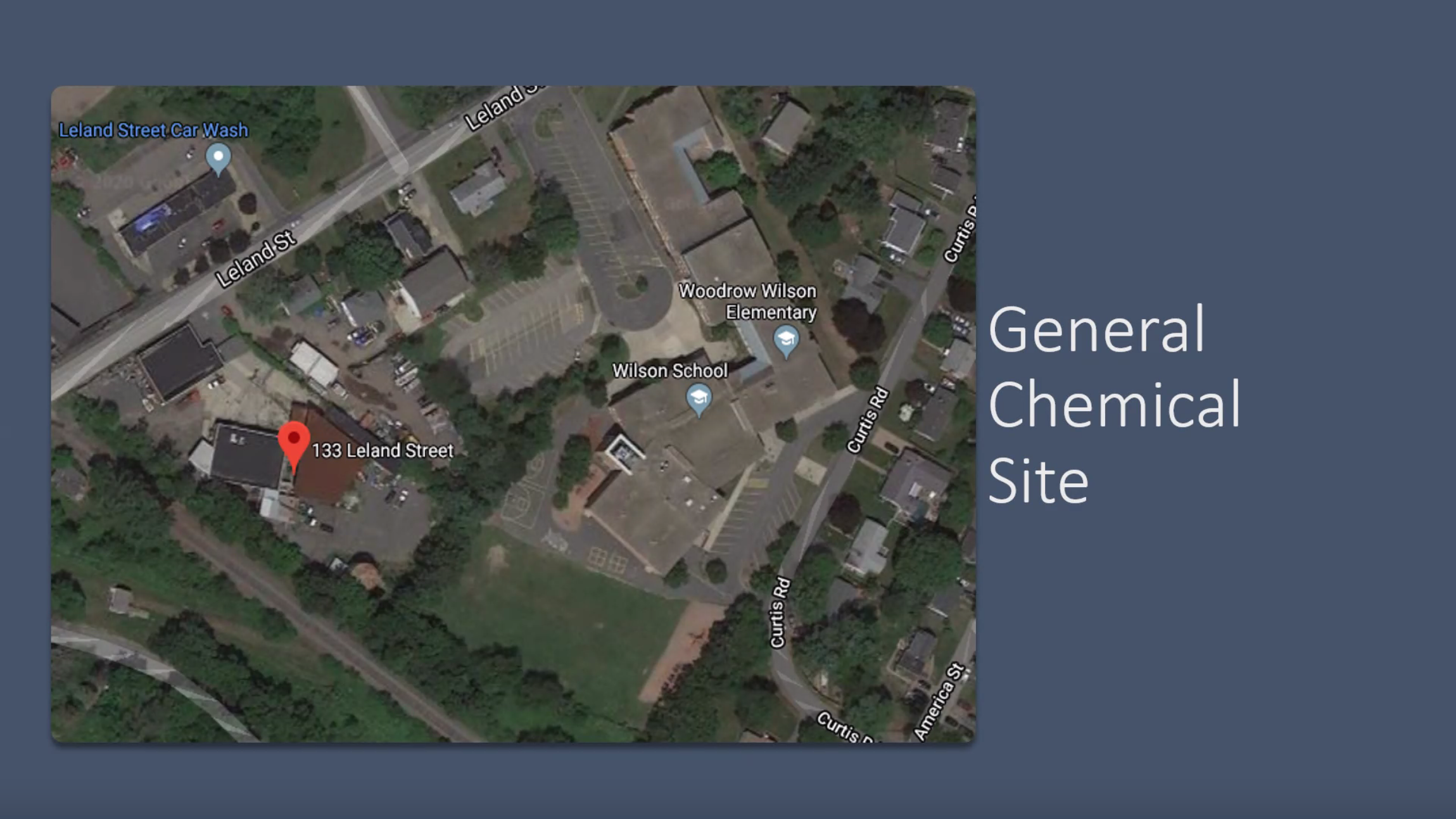

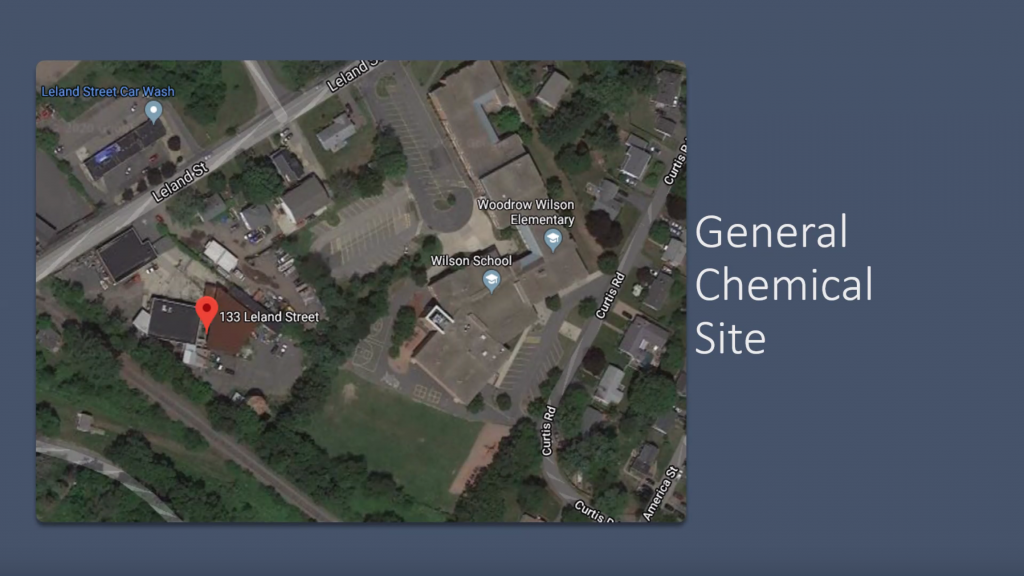

The General Chemical site is located at 133 Leland Street and was initially used as a bulk fuel terminal by Gulf Oil in the 1920s. During the 1960s, the site began a hazardous waste treatment with storage and used solvent recycling. In the decades following the 1960s, multiple licenses were given and issued by MassDEP to the site.

In 2012, General Chemical ceased operations and began to plan and carry out decontamination of buildings, tanks, and equipment under MassDEP supervision. They were ordered to set aside over $1 million to clean up contaminated groundwater near the company in Framingham.

As of March 16, 2014, General Chemical and their property owner Trinity General have been required to keep testing and cleaning up contamination under an Administrative Consent Order. As of 2017, they have failed to comply with the order.

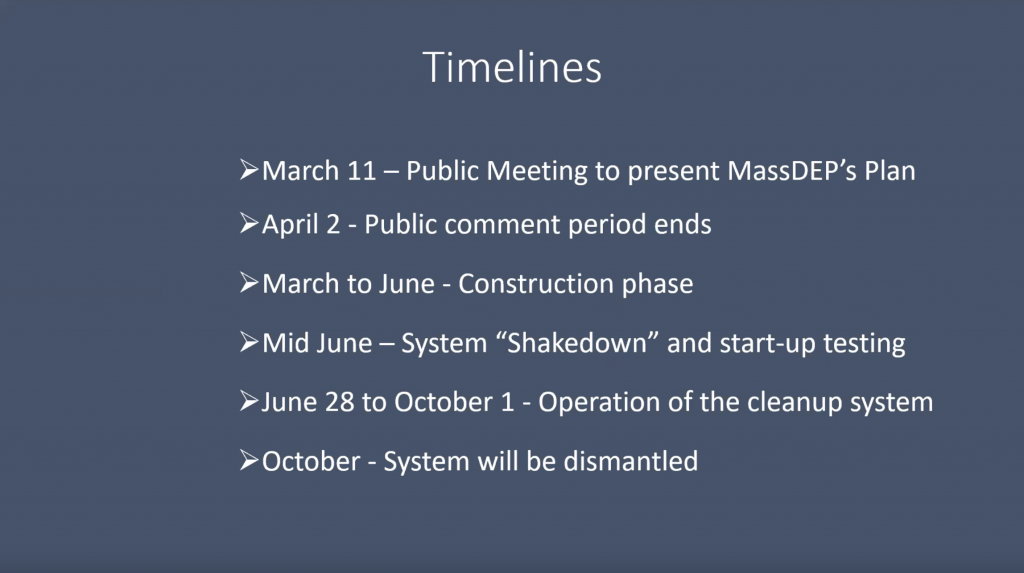

Drilling construction for the new project plans to start as early as next week, March 14, with the entire construction phase spanning up until June.

The public comment period for the project will end on April 2.

[broadstreet zone=”59982″]

Mid-June is when the system “shakedown” and start-up testing will begin.

June 28 to October 1 is when operation of the cleanup system will occur, followed by the dismantling of the system in October.

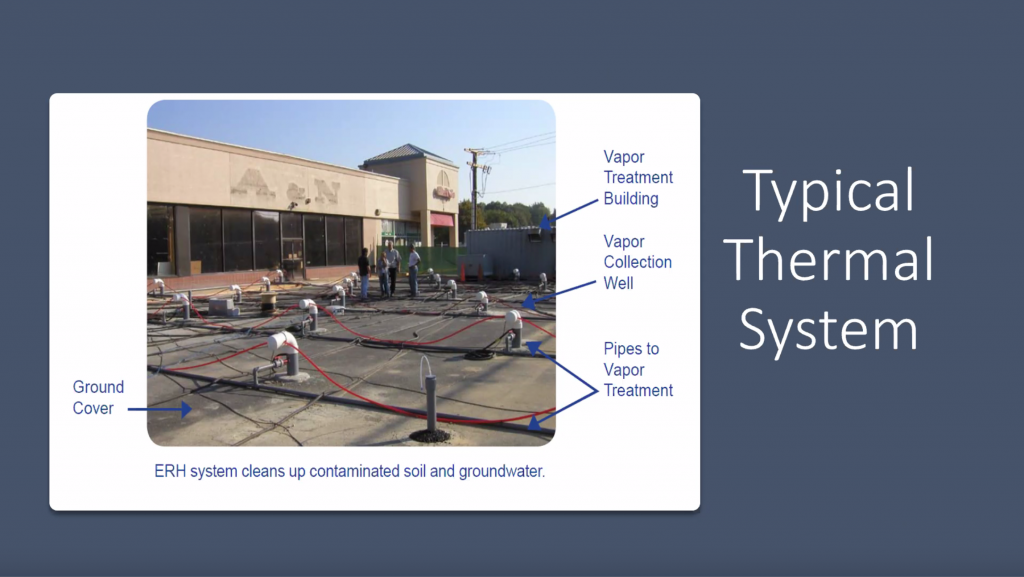

The contractor for the project will be TRS Group, Inc., who has done over 160 thermal treatment cleanups across North America.

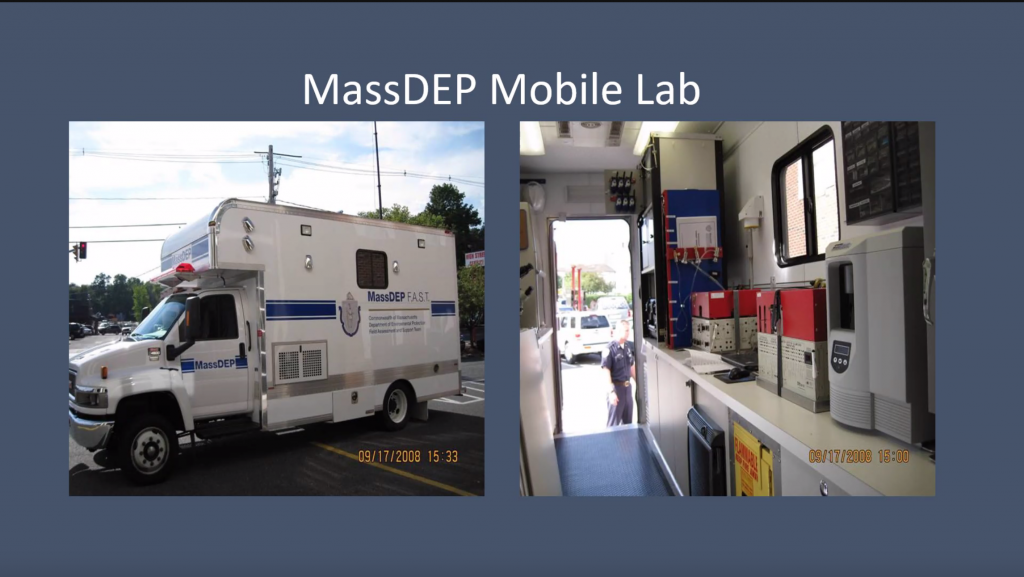

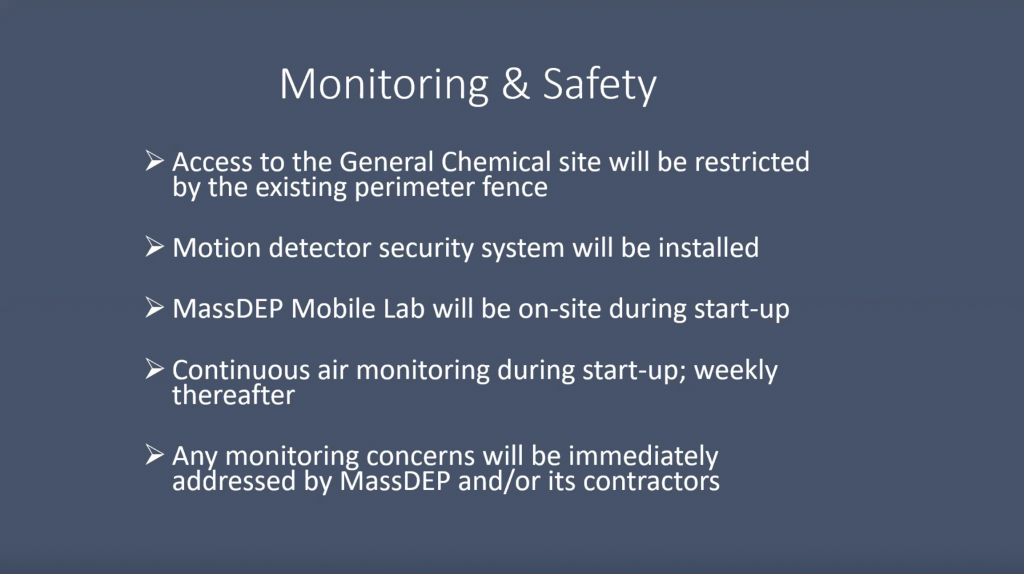

“TRS has 20 years of experience operating these types of systems. It is highly unlikely that operation of the system would ever result in a problem in the neighborhood based on the design and safety controls that are built into the system. In addition, MassDEP will be monitoring air quality in the surrounding neighborhood to ensure public safety,” writes the MassDEP in response to resident comments.

Despite the experience of the contractor and the effectiveness of the system, 100% of the contamination vapors will actually not be collected before release into the environment.

[broadstreet zone=”59946″]

“The system is designed to capture all the vapors generated from the subsurface and treat them using carbon filters. A minimum of 95% of the contaminated vapors will be removed by the treatment system before being released to the ambient air,” writes the MassDEP.

In terms of cost and exact numbers pertaining to the percentage of waste cleanup, it is still being determined, said MassDEP..

“MassDEP has retained the services of a state contractor (Aptim) to complete an updated Phase III Identification, Evaluation, and Selection of Comprehensive Remedial Action Alternatives. This evaluation is underway and will include a review of the various technologies and associated costs for cleaning up the entire Site. Once this document is complete, it will be available for public review,” writes the MassDEP.

The last estimate for the total cost of the project was around $2 million.

***

Luke Canavan is a spring 2021 SOURCE intern. He is currently a senior at the University of Massachusetts Amherst, where he studies Communication and English. He is passionate about film, television, writing, and literature, and upon graduation, he hopes to work in the entertainment industry full-time, where he can pursue his love for storytelling.

[broadstreet zone=”59984″]